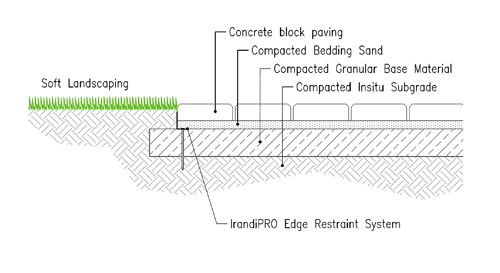

The purpose of the edge restraint system is to ensure that movement of the edge course is limited whilst dynamic loads resulting from use of the paved surface are imparted to the pavement structure. This ensures the integrity of the paved surface is maintained and kept looking as good as the day it was installed.

The below schedules illustrate typical light duty construction thicknesses against varying California Bearing Ratio (CBR) ranges for light duty residential uses.

TYPICAL PEDESTRIAN ONLY |

||||||

Surface Options |

Block Pavers |

Concrete Flags |

||||

Layers |

Surfacing |

> 50mm |

400x400x65mm |

|||

Bedding Sand |

25mm Compacted |

25mm Compacted |

||||

Granular Sub-base |

200 |

150 |

125 |

100 |

Nil |

|

Subgrade CBR (%) |

< 2 |

3 |

4 |

5 |

> 6 |

|

TYPICAL LIGHT VEHICLE |

||||||

Surface Options |

Block Pavers |

Concrete Flags |

||||

Layers |

Surfacing |

> 50mm |

400x400x65mm |

|||

Bedding Sand |

25mm Compacted |

25mm Compacted |

||||

Granular Sub-base |

275 |

230 |

200 |

175 |

150 |

|

Subgrade CBR (%) |

< 2 |

3 |

4 |

5 |

> 6 |

|